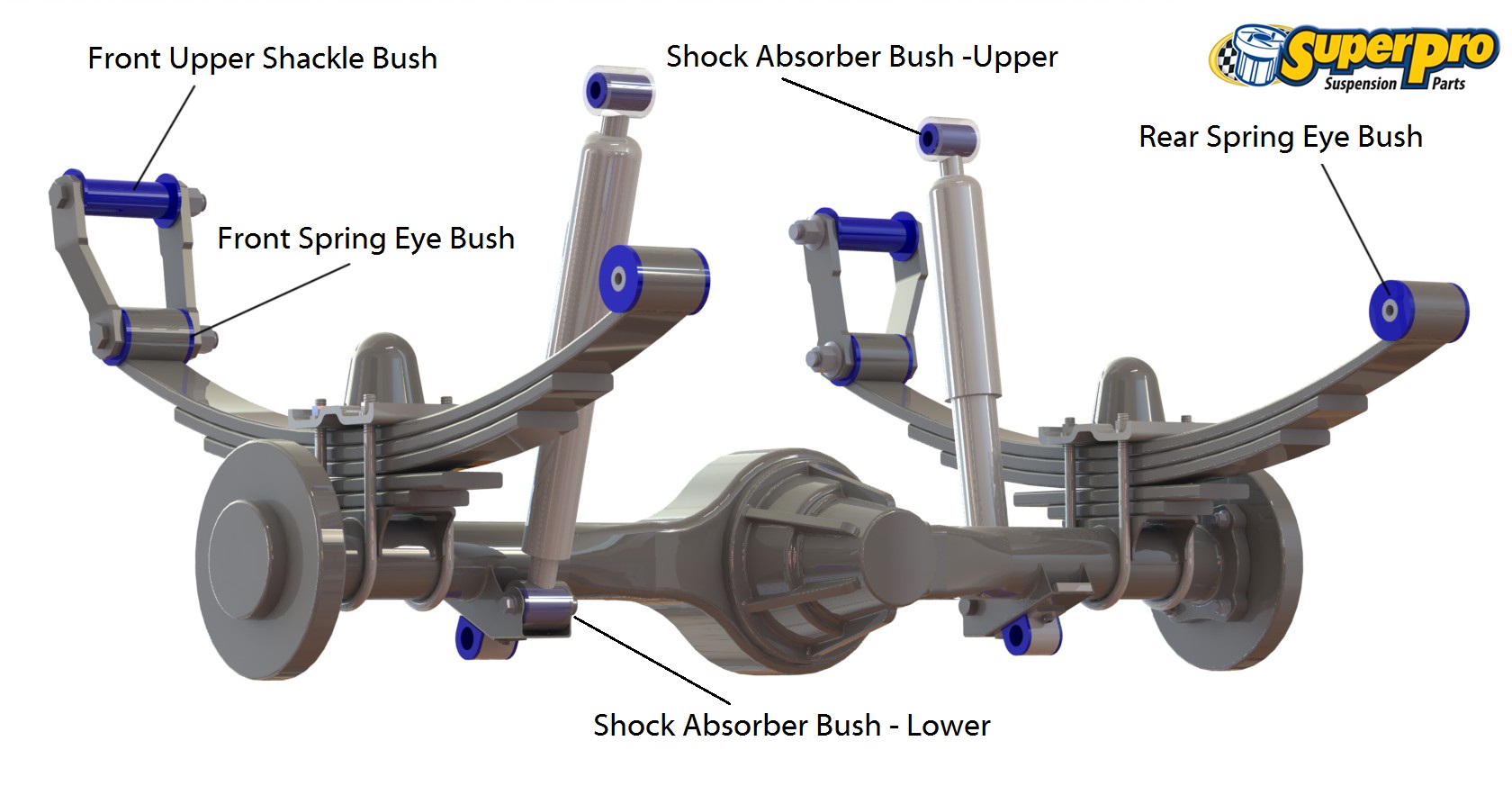

SuperPro Suspension Parts and Poly Bushings for Front & Rear Leaf Spring Models 19922002

• Leaf spring suspension designs have two anti roll bar effects. The springs are stiff in roll (twist) which counteracts the vehicles roll motion if the. Figure 5: Force deflection diagram for front bushing c (p1y,p2y,p1z,p2z) and w (p1y,p2y,p1z,p2z) for the front bush-ing. This results in a force deflection diagram for the

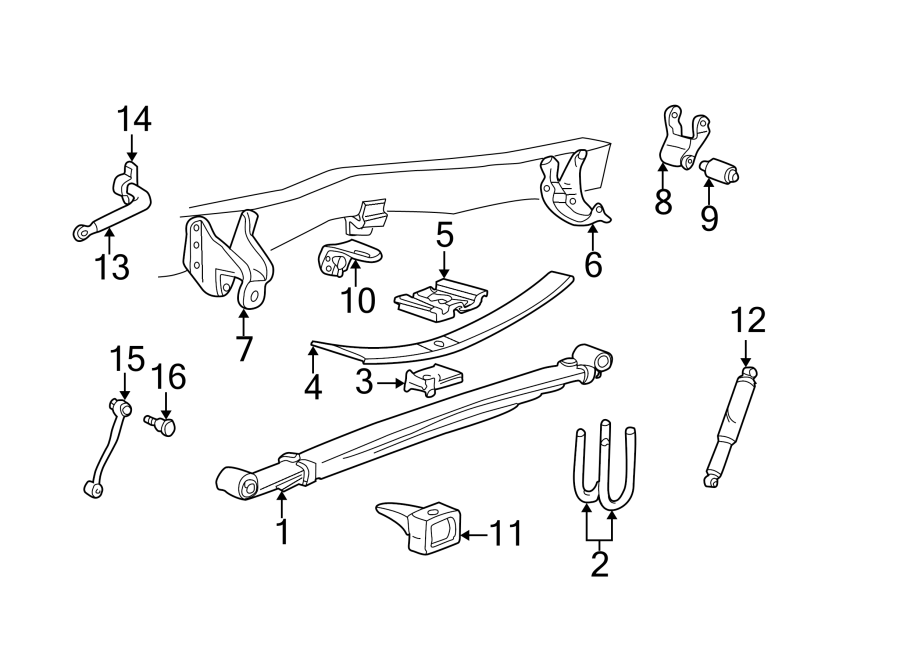

F81Z5598DA Ford Leaf Spring Spacer. 4WD, 156, 158, 172 WB Lakeland Ford Online Parts

L = The characteristic length of the spring. Therefore, once the design parameters, given on the left side of the above equation, are fixed the value of plate thickness, h can be calculated. Substitution of h in the stress equation above will yield the value of plate width b. F = Force applied to leaf spring.

Repair Guides Rear Suspension Leaf Springs

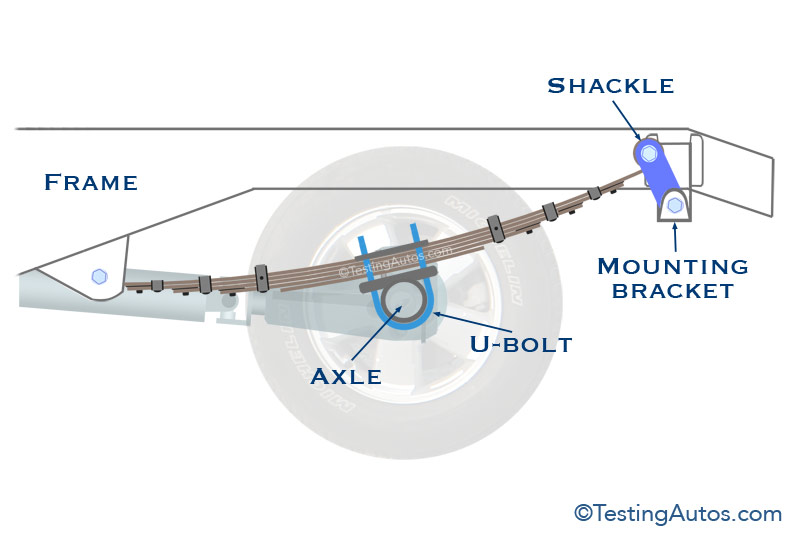

A leaf spring is a simpler spring used universally for suspension systems in light and heavy commercial vehicles. For cars, these are widely used for the rear suspension. Sometimes it is also known as a semi-elliptical, elliptical, or carriage spring. It is one of the oldest spring forms, appearing on trains in France in the 1970s.

Leaf Spring R&R Isn't A Hard Task, And Is SOmething You Can Do At Home

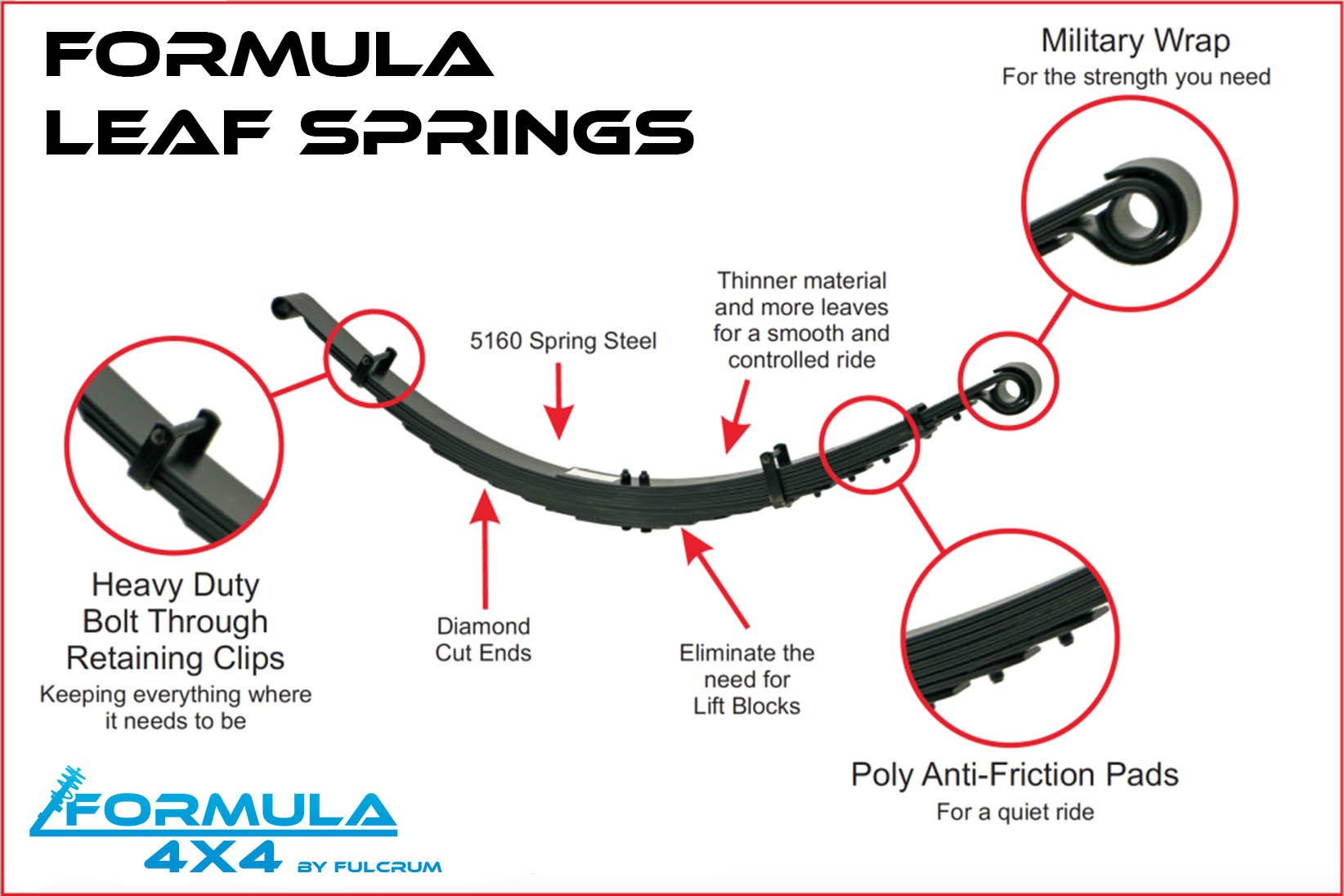

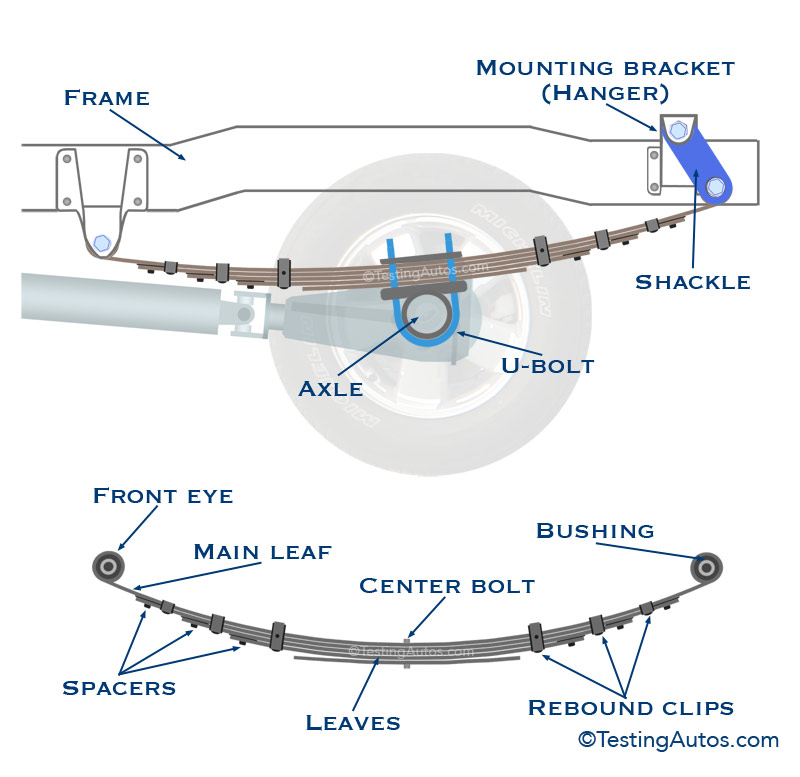

Leaf springs are a basic form of suspension made up of layers of steel of varying sizes sandwiched one upon the other. Most leaf spring setups are formed into an elliptical shape through the use.

car suspension leaf spring diagram

Leaf springs, unlike coil springs, also placed the back axle, removing the requirement for trailing hands as well as a track bar, resulting in a lower cost and weight for an efficient stay axle rear suspension [18, 19]. A leaf spring is composed of several plates of varying lengths that are connected with each other by clamps and bolts.

Repair Guides Rear Suspension Leaf Spring

FED15 calculates load-deflection line of the loaded leaf spring. Goodman-Diagram. If dynamically loaded, Goodman diagram is useful to calculate fatigue strength safety and bearable load cycles of the spring. Quick View. Load-deflection diagram together with tables of the essential spring data and results are printed on one page.

Repair Guides Front Suspension Leaf Springs

Before the days of every car leaving the factory with upper and lower control arms, or four-link suspensions, passenger cars had leaf springs that connected to either a car's unibody or frame fore and aft of the rear end, using a shackle to go between the frame or unibody at the rear. The leaf springs were attached to the rear end via U-bolts.

Cleaning and checking leaf springs How a Car Works

Leaf springs are the oldest form of suspension in racing. Although they are the oldest, they seem to be the least understood. Leaf springs possess many desirable suspension features, such as dampening, forward bite, roll over steer, high anti-squat percentage, and high lateral stiffness.

Front leaf spring based suspension system featuring a 2leaf spring Download Scientific Diagram

Introduction. Leaf Springs are widely used in the automobile and railway industries for suspension applications. The simplest variation is the single beam spring. The more normal application is the laminated (multiple) leaf spring which provides a more efficient stress distribution.. Single Leaf Springs have the following characteristics.

Repair Guides Rear Suspension Leaf Springs

Leaf springs are essential elements in the suspension systems of vehicles including sport utility vehicles, trucks, and railroad vehicles. Accurate modeling of the leaf springs is.

Leaf Spring Suspension Leaf Springs Fulcrum Suspensions

A leaf spring is a simple form of spring commonly used for suspension in wheeled vehicles. Originally called a laminated or carriage spring, and sometimes referred to as a semi-elliptical spring, elliptical spring, or cart spring, it is one of the oldest forms of vehicle suspension.

Under Leaf Spring Suspension Diagram

While new Jeeps and SUVs these days typically come with coil springs, leaf springs still exist on the rear of most pickup trucks (Ram 1500s and 2500s being the exception). Leaf springs are the most simplistic and inexpensive suspension system for your 4×4. The basic technology has been around since the days of covered wagons.

Repair Guides

Leaf springs possess many desirable suspension features, such as dampening, forward bite, rollover steer, high anti-squat percentage, and high lateral stiffness. In addition, the leaf spring suspension is more forgiving on chassis set-up errors.

Leaf Spring vs Coil Spring Suspension System

Apr 27, 2020 We've often touted the benefits of leaf spring suspensions. Sure, they are simple. Sure, its technology that could be almost 300 years old, and sure, leaf springs aren't.

Cleaning and checking leaf springs How a Car Works

By: John Fuller Would a pair of leaf springs help out this sorry state? Probably not, but trailers built with leaf-spring capabilities are much better at carrying heavy loads. Mark Horn/Getty Images Before you start your towing trip, it's a good idea to go over a brief checklist -- for safety's sake.

Under Leaf Spring Suspension Diagram

Leaf springs are a crucial part of the suspension system of a car. They consist of a number of layers of leaves with a gradation in their size, the bigger layer being on the top with each layer joined to the other. Leaf springs are directly attached to the frame, either at both ends or at one end.